Introduction

If you’ve been running a sportswear brand, you may have heard the term “sublimated jersey definition” thrown around in conversations about custom apparel. A sublimated jersey is produced using a specialized printing process where dyes are transferred into the fabric rather than just printed on the surface. This creates vibrant, long-lasting prints that don’t crack or peel over time.

According to recent market data, the U.S. dye sublimation printing market generated a revenue of USD 3,323.5 million in 2024 and is projected to reach USD 6,764.4 million by 2030. Much of that growth is driven by sports apparel, which accounts for over 77% of the end-user market share in sublimation printing.

For many print shop owners and teamwear brands, understanding the “sublimated jersey definition” is essential for staying competitive. Whether you print for local sports teams or manage a large-scale apparel business, sublimation can offer your customers high-quality products with brilliant colors.

It also caters to growing trends in customization, sustainability, and comfort. In this post, we’ll walk you through how the process works, the key benefits, the necessary materials, and how to make the most of this technology.

Sublimated Jersey Definition: How It Works

A sublimated jersey may look like any other polyester top, but there is a lot going on behind the scenes. In “sublimated jersey definition,” you start by creating your design on a computer, often using graphic software such as Adobe Illustrator or CorelDRAW. These platforms let you work with vector graphics, ensuring that your images remain clear no matter how large or small you print them.

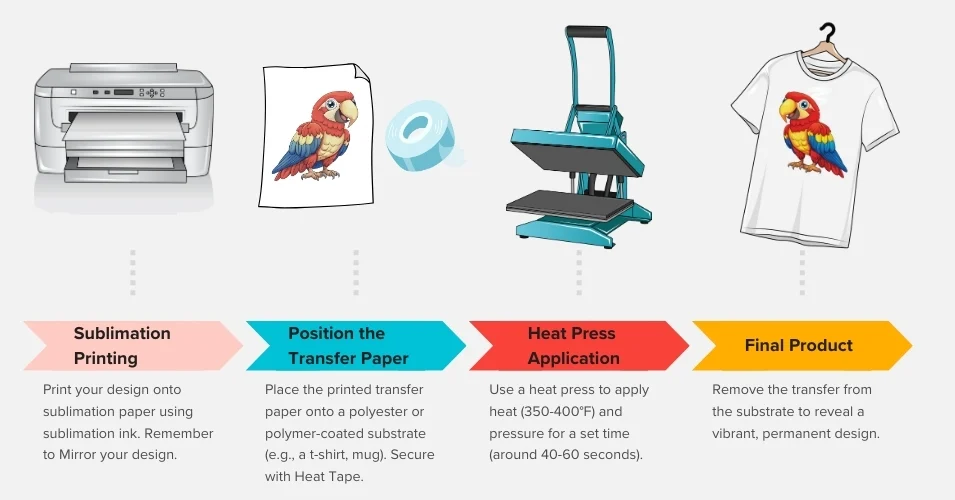

Once your design is ready, you print it onto a special transfer paper using sublimation ink. This is where the magic happens. The printed design is placed on the polyester jersey, and a heat press is used to apply high heat and pressure.

The heat turns the ink into a gas, which permanently bonds with the polyester fibers. This means the design becomes part of the jersey itself, rather than resting on top. Because polyester is the fabric of choice, it best captures the dyes and keeps them vibrant wash after wash.

Sublimation Market Trends

Many apparel companies are jumping into dye sublimation because of rising consumer demand for unique, personalized products. Trends such as on-demand production and e-commerce customization have fueled this market’s growth.

Major research suggests that in Asia Pacific alone, the sublimation printing market could reach over USD 380 million by 2030, with a CAGR of more than 12%. As more customers look for ways to add custom logos, team names, and intricate graphics to sportswear, sublimated jerseys continue to gain traction.

Sublimated Jersey: Key Benefits

When we talk about “sublimated jersey definition,” we are focusing not only on how these jerseys are made but also on what makes them stand out. Below are the main advantages that make sublimation a popular choice:

- Vivid Colors and Detail

Sublimation dye transforms into gas under high heat and fuses directly with polyester fibers. This produces vibrant, crisp images that remain bright even after multiple washes. - Longer Lasting Prints

Because the design is embedded into the fabric, it won’t crack, peel, or fade. This is a huge benefit for sports teams that need jerseys to withstand intense action and frequent laundering. - Full-Custom Design Possibilities

Sublimation allows for all-over prints, so you can wrap a design around the entire jersey without the limitations of screen size or certain placement restrictions. - Comfortable Fabric Feel

With sublimation, the finished jersey retains the polyester’s original feel. You won’t feel ink layers or raised patches, making the garment more breathable and comfortable. - Eco-Friendly Options

Recent sustainability initiatives include water-based inks and other eco-friendly practices. Many businesses embrace these solutions to reduce their environmental footprint.

By leveraging these benefits, businesses stay ahead in a competitive market. Industrial printing brands like Mimaki Engineering Co., Ltd. and Roland DG Corporation offer printers that support seamless design-to-print workflows. This pushes the boundaries of what’s possible in creating custom sportswear, fashion items, and more.

Leading Companies in Sublimation

Whether you’re a small shop or a large-scale production house looking for top-tier equipment, you have plenty of options:

- Seiko Epson Corporation: Renowned for high-quality dye sublimation printers with precise color management.

- HP Inc.: Offers diverse printing solutions for businesses of all sizes, including specialized dye sublimation models.

- Sawgrass Technologies, Inc.: Provides complete sublimation solutions, from printer hardware to color management software.

- Kornit Digital Ltd.: Develops industrial-grade printers designed for high-volume apparel printing.

- Mutoh Industries Ltd.: Known for reliability and efficiency, particularly in large-format sublimation printing.

Sublimated Jersey: Materials and Tools

The “sublimated jersey definition” also includes understanding what goes into making these garments from start to finish. Traditionally, polyester is the fabric of choice because sublimation ink chemically bonds with polyester fibers. If the garment includes a polyester blend, it must have a high polyester percentage—usually at least 65%—to ensure the best color absorption.

Below are some essential tools and resources you’ll need:

- Sublimation Printer

Specialized printers use sublimation ink and can handle transfer paper. Product lines from Epson, Sawgrass, and Roland are popular in sportswear production. - Heat Press

A sturdy heat press is crucial for proper heat and pressure. Without consistent temperatures (usually around 380–400°F), the transfer won’t fuse properly with the fabric. - Transfer Paper

Quality transfer paper holds your design before pressing. Look for paper that feeds smoothly through your printer and releases ink effectively. - Sublimation Ink

These inks turn into gas when heated and permanently bond to the polyester fibers in your jersey. Inks from brands like Sawgrass or Epson are designed to maintain color consistency. - Graphics Software

Tools like Adobe Illustrator, CorelDRAW, and Wasatch SoftRIP allow you to create detailed designs and control color accuracy. Sawgrass CreativeStudio also provides templates for those just starting.

Essential Software Tools

- Adobe Illustrator: Excellent for vector-based graphics.

- CorelDRAW: Offers a robust set of illustration and photo-editing features.

- Sawgrass CreativeStudio: Simplifies design, especially for beginners.

- Epson Edge Print: Advanced RIP software for managing color profiles.

- Wasatch SoftRIP: Helps optimize workflows and fine-tune color fidelity.

With these materials in hand, you can produce consistent, high-quality sublimated jerseys. The process might require an initial learning curve, especially with color management, but modern software solutions help streamline tasks. In fact, automation and advanced digital technologies are among the top trends shaping the future of sublimation. Businesses are integrating these tools to not only improve print speeds but also reduce human error, leading to more cost-effective production.

Conclusion

In today’s custom apparel landscape, having a solid “sublimated jersey definition” under your belt can set you apart. Sublimated jerseys are popular for their vibrant images, long-lasting prints, and limitless design potential.

Given that the U.S. textile printing sector is on track to reach USD 6,764.4 million by 2030—a clear indication of growing demand—now is the perfect time to embrace this printing method. From youth leagues to professional teams, sublimation delivers color consistency and durability that push creative boundaries.

If you’re looking to capture a slice of this ever-expanding market, remember to invest in reliable equipment, learn proper heat press techniques, and choose the right software for color management. Paying attention to every detail helps you fully realize the power of sublimation.

By clearly understanding the “sublimated jersey definition,” you’ll provide your clients with state-of-the-art sportswear that stands the test of time—and keep your business at the forefront of custom apparel innovation.