Welcome to Sublimation Insider! In this post, we’ll explore how to create the most effective sublimation designs for teamwear, sports uniforms, and custom apparel. Sublimation printing has become one of the fastest-growing methods in the textile industry. In fact, the global dye sublimation printing market is expected to reach nearly USD 29 billion by 2032, growing at a rate of about 10.45%. This means more entrepreneurs, print shop owners, and apparel designers are discovering the potential of sublimation and leveraging it to produce vivid, long-lasting prints.

In this guide, you’ll learn how to master color accuracy, choose the right materials, and avoid common pitfalls when creating your sublimation designs. We’ll also look at specific companies, tools, and best practices you can use to succeed in this exciting niche.

Understanding Sublimation Designs

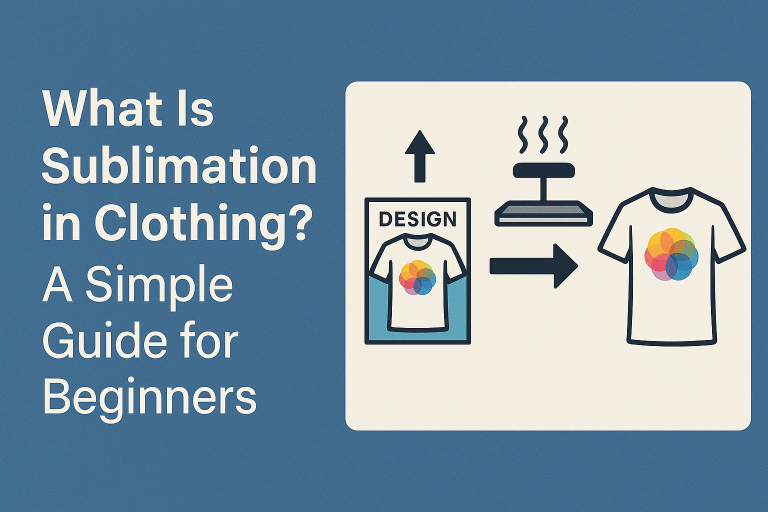

Sublimation designs are graphics intended for dye sublimation, which uses heat and pressure to transfer ink onto polyester-based fabrics. During the process, the ink turns into a gas that bonds with the fibers, creating a permanent image. This is different from other printing methods like screen printing because the design becomes part of the fabric itself rather than just sitting on top.

Today, sublimation designs are widely used for sports jerseys, activewear, and personalized apparel because the colors are vibrant, and the prints can withstand heavy use. Industry reports show that the textile printing market, which includes sublimation, is projected to grow at nearly 8.9% to USD 33.8 billion by 2027. Ultimately, understanding sublimation designs means knowing how to harness heat, ink, and the right materials to produce consistently sharp and durable prints.

Why Polyester Matters

Polyester is the go-to material for most sublimation designs because its fibers open up under high heat, allowing the sublimation ink to bond permanently. If you try sublimation on cotton or other fabrics, you won’t get the same level of color vibrancy and durability. That’s why many print shops and teamwear brands ensure their apparel is made from polyester or polyester blends with at least 65% polyester content.

Key Benefits of Sublimation

• Permanent and durable: The design won’t peel or crack.

• Vibrant colors: Sublimation inks create eye-catching prints.

• Breathable: Since the ink fuses into the fabric, it doesn’t affect breathability.

• Versatile: You can produce jerseys, leggings, masks, and more.

Setting Up Your Workspace for Sublimation Designs

Before you begin producing sublimation designs, you need to have the right equipment and a well-organized workflow. As the demand for dye sublimation continues to rise—research indicates the segment is expected to reach USD 25.52 billion by 2030—your workspace needs to be ready for efficient and high-quality production.

First, dedicate a clean, temperature-controlled area for printing and pressing. Keep your printer away from moisture and dust, which can clog printheads. You’ll also want a proper heat press that can maintain steady pressure and temperature. Companies like Roland DGA Corporation, Mimaki Engineering Co., and Sawgrass Technologies Inc. are well-known manufacturers of printers and heat presses that can handle everything from small-scale to large-scale operations.

Essential Tools and Software

- Adobe Photoshop or CorelDRAW: These allow for detailed editing and vector design work.

- Raster Image Processor (RIP) Software: Lets you manage color profiles for consistent results.

- Color Management Tools: Calibrate your printer and monitor for accurate color translation.

Properly setting up your workspace and equipping it with the right tools helps avoid scuffs, misprints, and wasted materials. An efficient layout will also help you process orders faster, which is crucial in an industry where customer demand can be high, especially during peak sports seasons.

Best Practices for Creating Sublimation Designs

Creating sublimation designs is more than just picking bright colors. You’ll need to consider ink behavior, fabric properties, files, and color management. The global dye sublimation transfer paper market for tacky papers is projected to grow by 7.3% in the coming years, signaling an increased emphasis on precision and alignment. Getting the best print depends on preparing your design files correctly and controlling variables like temperature and time during pressing.

Color Management Essentials

Proper color management is a key step in creating sublimation designs. Sublimation inks react differently from standard inks, so calibrate your printer and monitor to maintain consistent colors. Tools like RIP software or specialized color management programs analyze your images and produce the right color profile for each printer.

• Always convert your images to the desired color profile (often CMYK or a custom ICC profile) before printing.

• Perform regular test prints to confirm color accuracy.

• Store your inks and transfer paper in a cool, dry place to prevent any change in color performance.

Choosing the Right Substrates

Although polyester is the preferred choice, the amount of polyester in the fabric matters. Some performance fabrics are engineered specifically for athletic wear, offering moisture-wicking benefits and high elasticity. When you combine these advanced materials with your sublimation designs, you get high-quality, comfortable garments that maintain their vibrant prints through frequent washing.

Fabrics with higher polyester content (like 100% or 90% blends) often yield the most vivid colors. Double-check that your chosen substrate is sublimation-friendly by doing a small test press on a fabric swatch if possible.

Tips for Printing and Pressing Sublimation Designs

Once your setup is ready and your files are in top shape, it’s time to print and press your sublimation designs. According to recent data, the transfer dye sublimation printing segment alone generated revenue of over USD 9,499 million in 2024 and is projected to nearly double by 2030. This growth indicates a high volume of apparel being produced via sublimation, so standing out with quality is essential.

Leveraging the Right Tools

Your success in printing and pressing sublimation designs often comes down to the equipment you choose. Here are some tips:

• Printers: Look at options from Epson, HP, or Mutoh if you need reliability and consistent output. These brands provide different printer sizes that cater to both small and medium production runs.

• Ink: Use high-quality inks from recognized suppliers like Sawgrass Technologies Inc. or Fujifilm to reduce the chance of faded designs. Cheaper inks can lead to less vibrant prints and clogged nozzles.

• Heat Press: Check that your heat press can maintain consistent temperatures across the platen. Spotty heat will result in uneven prints.

Common Mistakes to Avoid

Even small hiccups can ruin your sublimation designs. Here are typical problems and how to avoid them:

- Incorrect Temperature or Time: Always follow the recommended guidelines for your fabric. Overheating can scorch or blur designs, while underheating leads to faint prints.

- Using the Wrong Transfer Paper: Not all sublimation papers are created equal. Tacky paper can help keep your design in place, preventing registration errors.

- Poor File Resolution: Low-resolution images lead to fuzzy prints. Use at least 300 DPI for high-quality results.

- Skipping Test Prints: Running a quick test can save you from wasting a full sheet of transfer paper and an entire garment.

By focusing on consistency and avoiding these common errors, you ensure that your sublimation designs come out vibrant and professional every time.

Conclusion and Future Outlook

The apparel industry is ripe with opportunities for those who master sublimation designs. Stats show that the Asia Pacific region alone accounts for almost half of the global digital pigment sublimation printer market. This expansion ties in with broader trends like on-demand production and eco-friendly ink development. Companies like ColorJet Group and Agfa-Gevaert are actively pushing the boundaries, introducing advanced sublimation printers that make it faster and easier to produce customized activewear, fashion apparel, and even automotive interiors.

Whether you are a small print shop owner or a designer for major sports teams, the keys to success remain the same: invest in quality equipment, fine-tune your color management, and continually adapt to new market trends. By following the best practices outlined in this post—from workspace setup to final pressing—you’ll create sublimation designs with superior color accuracy and unmatched durability.

As the global dye sublimation printing market edges closer to USD 29 billion, it’s clear that sublimation designs are here to stay. With the right approach, you can be part of the ever-growing community that’s revolutionizing how we design and manufacture custom apparel. So take these insights, perfect your processes, and watch your sublimation business flourish in this exciting segment of the textile industry.