Sublimation in clothing is an advanced printing technique that has gained popularity, especially for custom apparel like sportswear and team uniforms. If you are new to this printing process, don’t worry — this guide will break it down for you in simple terms. By the end, you’ll understand what sublimation is, how it works, and why it’s so popular for creating high-quality, durable designs.

What Is Sublimation in Clothing?

Sublimation in clothing refers to a printing method where a design is transferred onto fabric using heat. Unlike traditional printing techniques, sublimation uses heat and pressure to turn solid dye into gas, which then bonds with the fabric. This process creates vibrant, long-lasting prints that are ideal for polyester fabrics, which are commonly used in sportswear and custom apparel.

The key advantage of sublimation is its ability to produce designs that are embedded directly into the fibers of the fabric, rather than sitting on top like screen prints or heat transfers. This makes sublimated prints more durable and resistant to fading, cracking, or peeling over time.

Why Is Sublimation Ideal for Clothing?

Sublimation printing is especially popular for clothing because it offers several benefits:

- Vibrant Colors: Sublimation produces bright, eye-catching designs with a wide color gamut.

- Long-Lasting Prints: The dye becomes a permanent part of the fabric, ensuring that the design won’t fade easily.

- No Feel on the Fabric: Unlike other methods, sublimated prints don’t affect the texture or breathability of the fabric.

- Environmental Benefits: The process uses water-based inks, which makes it more eco-friendly than traditional methods.

How Does Sublimation Work in Clothing?

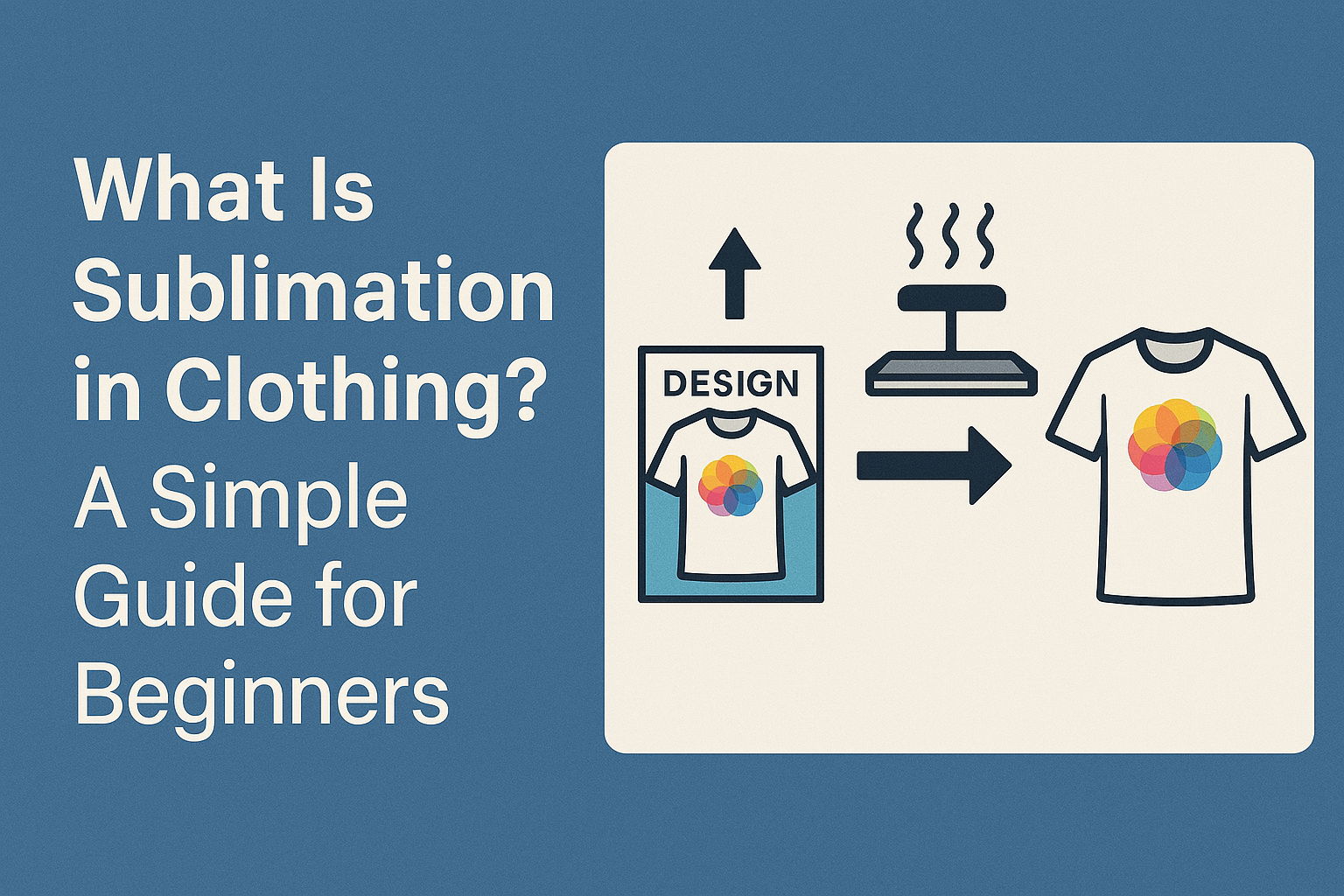

The sublimation process involves a few key steps: preparing the design, printing it onto transfer paper, and then using heat to transfer the design onto the fabric.

Step 1: Preparing the Design

Before sublimation printing can begin, the design must be created. This is typically done using graphic design software such as Adobe Photoshop, CorelDRAW, or even free programs like GIMP or Inkscape. The design is then mirrored so that it appears correctly when transferred onto the fabric.

Step 2: Printing the Design

Once the design is ready, it is printed onto special sublimation transfer paper using sublimation ink. This ink has unique properties, allowing it to turn into a gas when heat is applied, instead of melting into a liquid like other types of ink.

Step 3: Transferring the Design

The transfer paper with the printed design is then placed on the fabric, and a heat press machine applies both heat and pressure. The heat causes the dye to sublimate — meaning it turns into a gas and bonds directly with the polyester fibers in the fabric. This results in a vibrant, permanent print that won’t wash off or peel over time.

Step 4: Finishing Up

Once the transfer is complete, the garment is cooled and ready for use. The design has now become a part of the fabric, making it incredibly durable and resistant to fading.

Materials Best for Sublimation in Clothing

Sublimation works best on certain types of materials. To achieve the best results, you’ll want to use polyester fabrics or fabrics with a high polyester content. Other synthetic fabrics that contain polyester, such as polyester-blend materials, are also good candidates for sublimation.

Why Polyester is Ideal for Sublimation

- High Dye Affinity: Polyester fibers have a strong attraction to sublimation inks, allowing the dye to bond properly and create vibrant, long-lasting prints.

- Durability: Polyester fabrics are durable and can withstand the heat required during the sublimation process without losing their shape or texture.

- Flexibility: Polyester is breathable and stretchable, making it perfect for sportswear and activewear, where comfort is key.

Other fabrics, such as cotton, are not ideal for sublimation printing because they do not allow the dye to bond effectively. This can lead to poor-quality prints that may fade or wash off.

Benefits of Sublimation in Clothing

Sublimation printing is gaining momentum in the world of custom apparel because it offers several advantages over traditional printing methods. Here are some key benefits:

1. High-Quality Prints

Sublimation printing produces high-definition, vibrant colors that are perfect for detailed designs. The ink becomes part of the fabric, so there’s no risk of the print cracking or fading over time.

2. Durability

Since the ink bonds with the fibers of the fabric, sublimated prints are incredibly durable. They won’t crack, peel, or fade, even after repeated washing.

3. Customization

Sublimation allows for easy customization. Whether you’re designing sports uniforms, team gear, or personalized apparel, sublimation can bring your ideas to life with precise detail and color accuracy.

4. Eco-Friendly

Unlike traditional printing methods, which often use harmful chemicals and produce excess waste, sublimation uses water-based inks and produces minimal waste, making it a more eco-friendly option.

5. No Feel on the Fabric

Sublimated prints don’t sit on top of the fabric like screen prints or heat transfers. The ink is absorbed into the fibers, which means there’s no extra texture or weight added to the fabric, making it soft and breathable.

Challenges and Considerations for Sublimation in Clothing

While sublimation offers many benefits, there are some challenges to consider before diving into the process.

Limited to Polyester Fabrics

Sublimation works best on polyester or polyester-blend fabrics. While it’s possible to sublimate on other materials, like cotton, the results may not be as vibrant or long-lasting.

Color Matching

Sublimation allows for a wide range of colors, but it’s important to note that the colors you see on your screen might not be exactly the same when printed. This is because monitors use RGB color profiles, while sublimation prints use the CMYK color profile, which can lead to slight color differences.

Special Equipment

To get started with sublimation printing, you’ll need specialized equipment, including a sublimation printer, transfer paper, and a heat press. These tools can be an investment, especially for small businesses or hobbyists.

Conclusion

Sublimation in clothing is a fantastic method for creating high-quality, durable, and customizable prints, especially on polyester fabrics. Whether you are designing sports uniforms, team gear, or personalized apparel, sublimation offers vibrant, long-lasting results that traditional printing methods can’t match.

With its growing popularity and demand for customized apparel, learning about sublimation could open up exciting opportunities for creators and businesses alike.